Laser Cutting vs. CNC Punching: Which is Better for Your Sheet Metal Project?

When designing a sheet metal part, choosing the right fabrication process is one of the most important decisions you’ll make. Two of the most common cutting methods—laser cutting and CNC punching—each offer unique advantages depending on your part geometry, volume, and material requirements.

Understanding the differences helps engineers, buyers, and manufacturers choose the most cost-effective and efficient process. Below, we break down how the two methods compare and when each one is the smarter choice.

What Is Laser Cutting?

Laser cutting uses a high-powered, focused beam of light to melt or vaporize material along a programmed path. Modern machines can cut extremely tight geometries with outstanding accuracy.

Key Advantages of Laser Cutting

1. Incredible precision and edge quality

Laser cutting produces clean, smooth edges with minimal burring—ideal for cosmetic parts or components requiring tight tolerances.

2. Complex and intricate shapes

If your design includes small radii, tiny holes, interior cutouts, or detailed contours, a laser excels.

3. Fast setup and short lead times

Laser cutting requires no tooling, which makes it ideal for prototypes and small-to-medium production runs.

4. Versatility in materials

Works well with steel, stainless, aluminum, copper, and other metals across a variety of thicknesses.

Best Uses for Laser Cutting

High-precision components

Parts with complex geometries

Low- to mid-volume production

Cosmetic or customer-facing parts

Rapid prototypes

What Is CNC Punching?

CNC punching uses a turret press equipped with hard tooling that stamps or punches shapes into sheet metal. A single machine can hold dozens of tools, allowing fast cycle times for repeated operations.

Key Advantages of CNC Punching

1. Cost-effective for high-volume parts

Because punching relies on tooling, cycle times are fast and consistent—ideal for medium- to high-volume production.

2. Integrated forming operations

Punch machines can do more than just cut. They can also create:

Louvers

Embosses

Countersinks

Taps

Offsets

Knockouts

This can eliminate secondary processes and reduce labor costs.

3. Fast cutting of simple shapes

For parts with many holes or repetitive shapes, punching is often faster (and cheaper) than laser cutting.

Best Uses for CNC Punching

High-volume production

Parts with repetitive patterns or many holes

Projects requiring formed features

Designs that can be produced with standard tooling

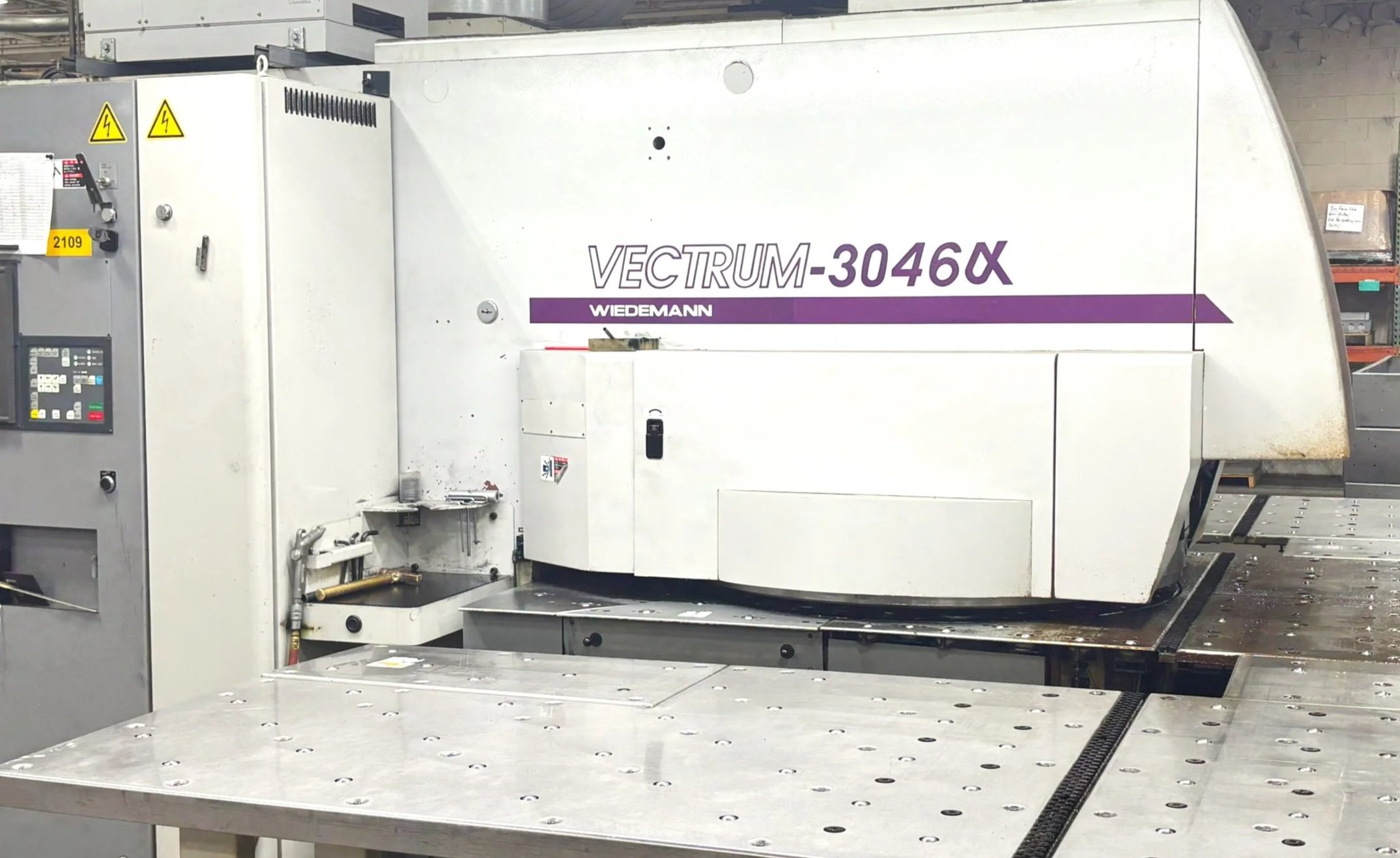

Murata Wiedemann Vectrum 3046 Turret Punch Press

So, Which Should You Choose?

Choose Laser Cutting When:

Your design has complex shapes or tight tolerances

You need a quick turnaround or prototype

Cosmetic quality matters

You want to avoid tooling costs

Choose CNC Punching When:

You’re producing high-volume parts

Your part needs features like louvers, countersinks, or embosses

Your design uses repetitive holes or simple shapes

You want the lowest cost per part over long production runs

Laser + Punching: The Hybrid Approach

Many modern sheet metal shops, including ours, use both technologies together. For example:

Punch the repetitive holes and form features

Laser cut the complex contours or internal shapes

This hybrid method lowers cost while maximizing precision and capability.

Final Thoughts

Both laser cutting and CNC punching are powerful tools in sheet metal fabrication. The best method depends on part geometry, production volume, and feature requirements. If you're unsure which process is right for your project, we can help evaluate your design and recommend the most efficient, cost-effective option.