Precision CNC Turret Punching Services

CNC turret punching offers high-speed, precise metal fabrication with minimal waste. It enables complex designs, quick tool changes, and consistent repeatability—ideal for the efficient, cost-effective creation of 2 or 3 dimensional cuts, flanges, louvers, card guides, extrusions, embossments, slits, taps, countersinks, or similar applications. Our customer will benefit from:

Fast Production:

Our punch presses speed up production by automating high-speed punching, rapid tool changes, and precise part positioning, significantly reducing cycle times and manual intervention in sheet metal fabrication.

High Quality/Tight Tolerances:

Our turrets also deliver high-quality results through precise, repeatable punching with tight tolerances, minimizing defects and ensuring consistent part accuracy across large production runs.

Cost Efficiency:

We reduce costs by minimizing material waste, lowering labor requirements, and enabling faster production cycles, making them highly efficient for medium to high-volume runs.

Murata Wiedemann Vectrum 3046

-

33 ton, 54 stations

Punches up to .250” mild steel

-

33 ton, 40 stations

Punches up to .250” mild steel

Max Punch diameter: 4.75”

Sheet Size (no repositioning): 50” x 80”

-

22 ton, 22 stations

Punches up to 6 mm mild steel

Max Hole Diameter: 3”

Sheet Size (no repositioning): 40.5” x 50”

Versatility, Precision, Speed

Our CNC punching services excel in fast, accurate sheet metal fabrication, leveraging programmable tool paths, rapid tool indexing, and minimal repositioning for complex geometries.

The Wiedemann Vectrum 3046—33‑ton (30 US ton) servo‑hydraulic turret—offers punching at 400 HPM, nibbling at 1000 HPM, ±0.07 mm accuracy, 54 stations (with auto‑indexing), and handles 1250 × 2000 mm sheets up to 6.35 mm thick.

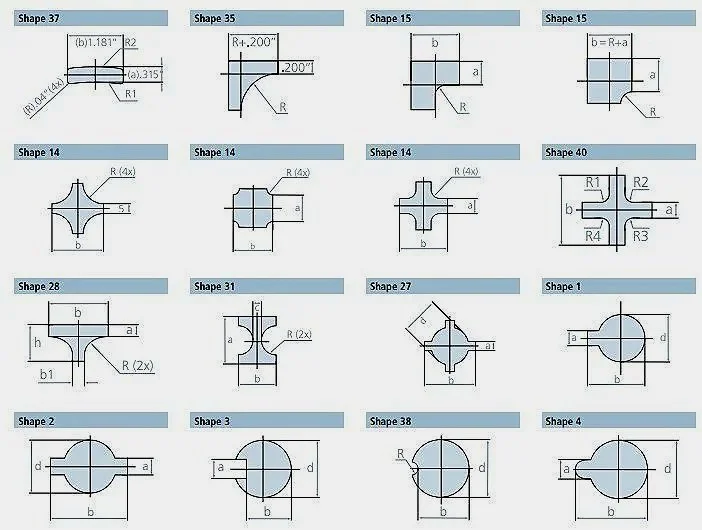

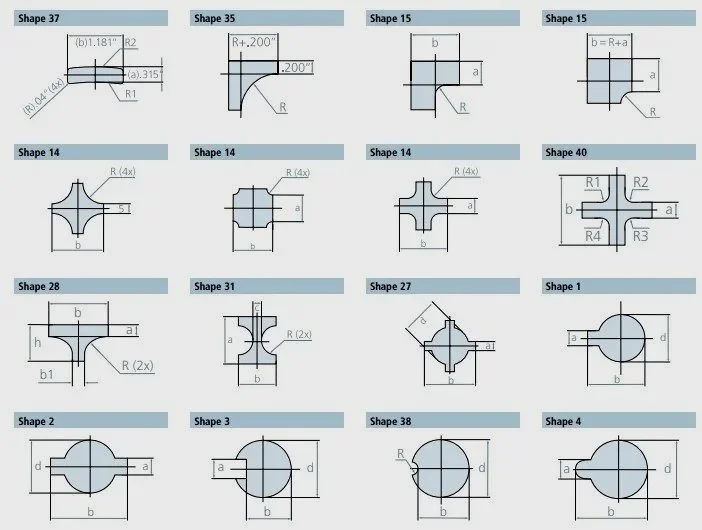

Turret Punch Tools

Our large tooling library allows us to tackle a wide variety of tasks and minimize the need for custom tooling.