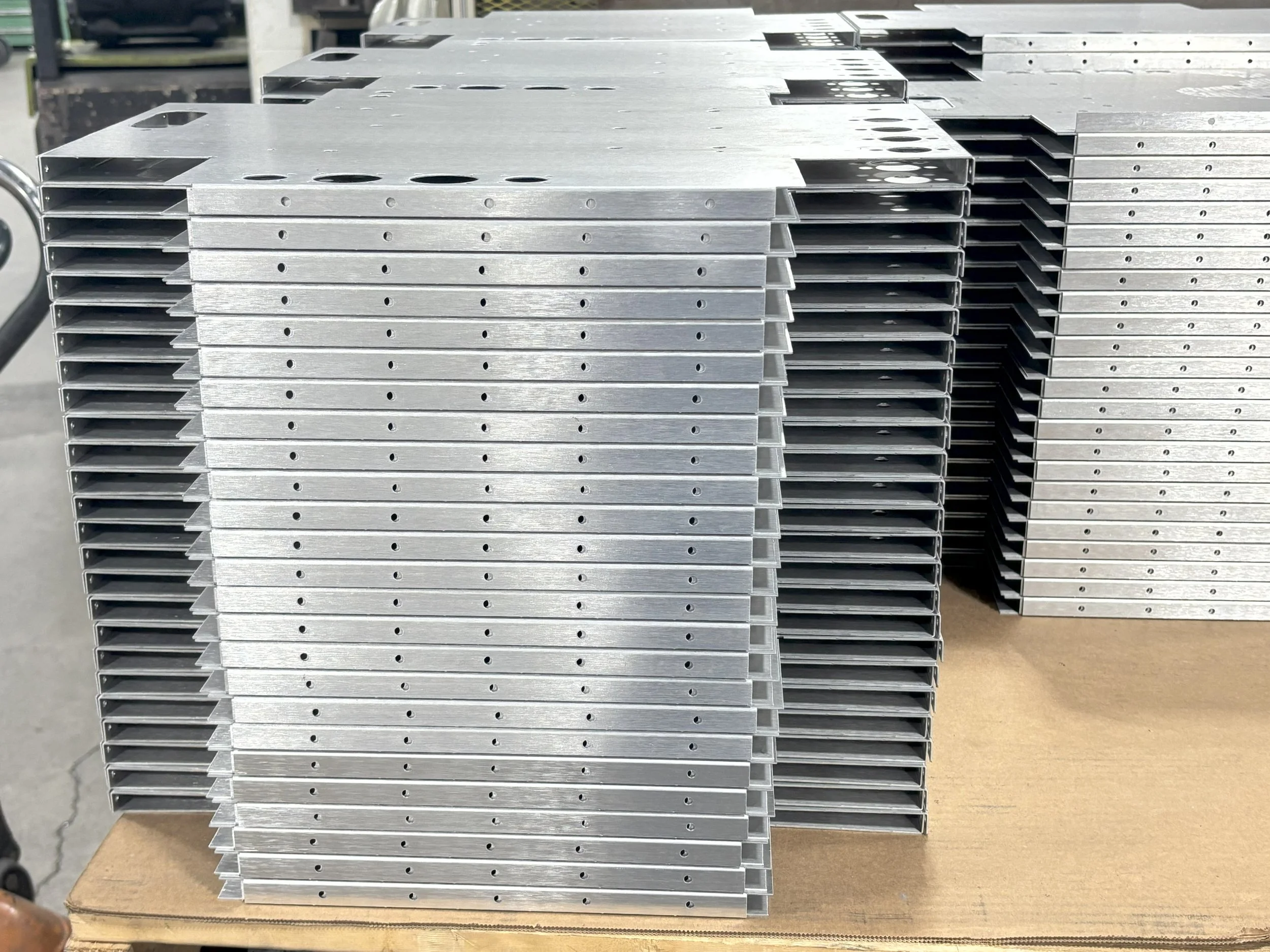

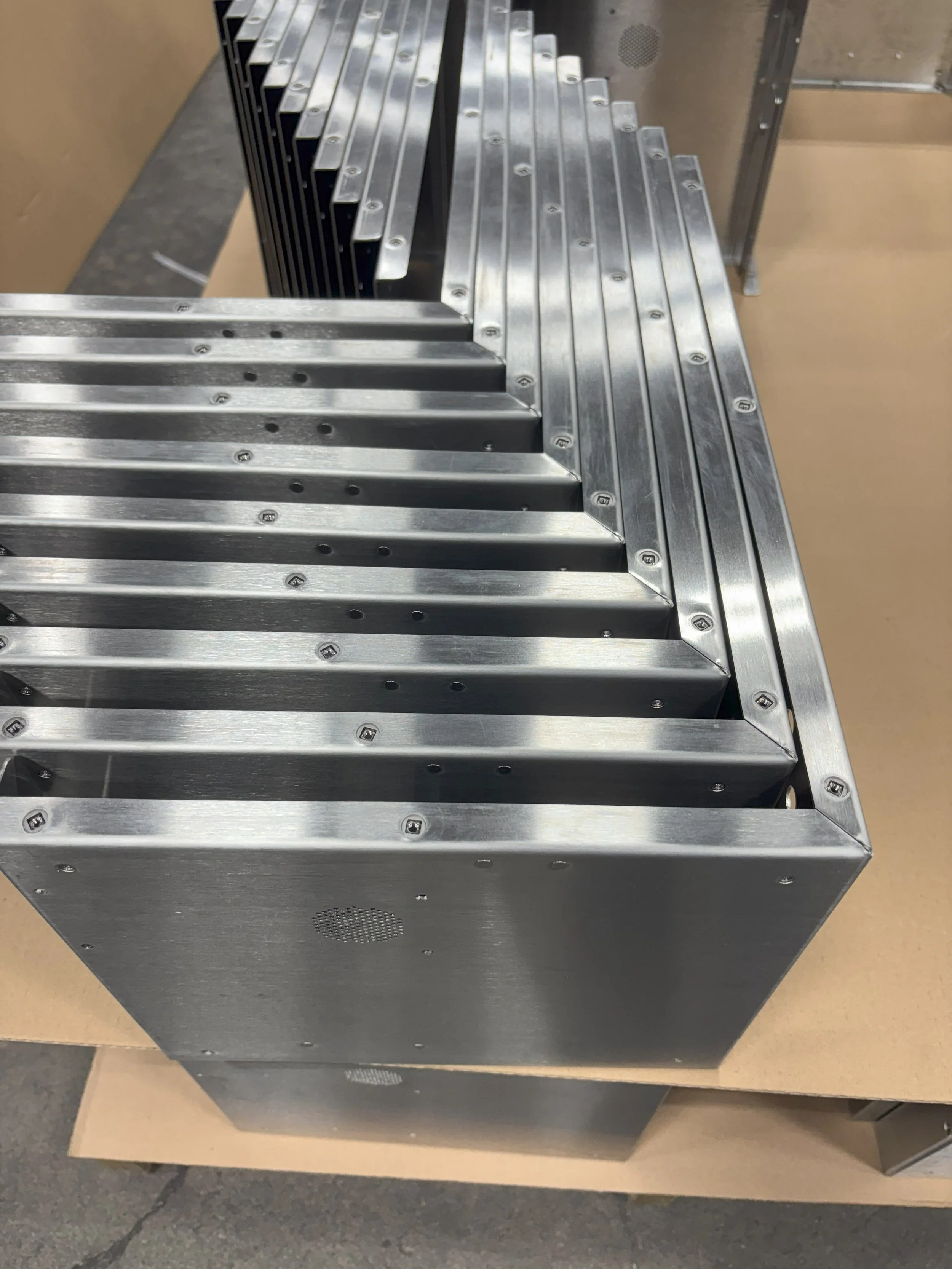

Custom Press Brake Forming for Sheet Metal

Expertly Formed

At ELO Engineering, we offer precision press brake forming as a core sheet metal service, delivering accurate, high-quality bends for components such as enclosures, brackets, and structural parts. Using advanced CNC press brakes, we handle a wide range of materials and thicknesses with exceptional precision.

Our equipment features programmable controls, multi-axis backgauges, and angle verification systems, ensuring tight tolerances and consistent results. Whether you need prototypes or high-volume production, our press brake forming service guarantees efficiency, repeatability, and superior part quality.

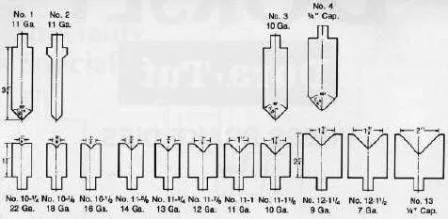

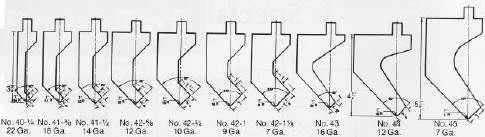

Advanced Tooling for Precision Bending

At ELO, we offer a comprehensive range of precision press brake tooling to meet diverse forming needs. Our tooling solutions ensure accuracy, efficiency, and repeatable quality across all projects.

Acute Tooling – Ideal for air bending applications requiring angles under 90°.

Gooseneck Punches – Designed for forming complex parts with return flanges.

Bottoming Dies – Ensure tight tolerances and reduced springback for high-precision bends.

Our suite of press brakes offers an impressive range of forming options:

(1) 135 Ton 8' Cincinnati Autoform Press Brake with Automatic Back Gauge

(1) 175 Ton 8' Cincinnati Autoform Press Brake with Automatic Back Gauge

(1) Amada 186 Ton 10' with Automatic Back Gauge

(1) 90 Ton 8' Cincinnati Autoform Press Brake

(1) 135 Ton 10' Cincinnati Autoform Press Brake with Automatic Back Gauge

(6) 60 Ton 6' Cincinnati CBII Press Brake with Automatic Back Gauge