Design-Driven Metal Fabrication Services

ELO Engineering stands out among our competitors by having a lot of services under our control. We can do a lot of things for our clients without having to outsource projects or services. This gives us tighter control of our timeline and production schedule, allowing us to get projects done faster than some of our competitors.

Having great outsourcing partners is wonderful. But even with a great partner, you are subject to their time table for turning your projects. By having many sheet metal fabrication services in house, we are able to eliminate that risk. In short, we cut sheet metal, smooth the edges, bend it, insert parts like PEM nuts, weld it, grind it, treat it, paint it and assemble it. And we can often do so in five weeks or less.

After our sheet metal gets cut, we take any rough edges off with our Deburring equipment.

After welding, they move into our cosmetic level grinding department.

Weld Spatter is cleanly ground by hand.

Some of our projects then move to Machining for milling in our CNC machining centers, or have holes drilled at one of our drill presses.

After we have smooth parts, we take it to our pre-treatment line where the metal is cleaned and prepared for paint.

Once those parts have been cleaned and dried, they go to our paint department, where they are sprayed with liquid or powder coat and sent to our ovens to bake.

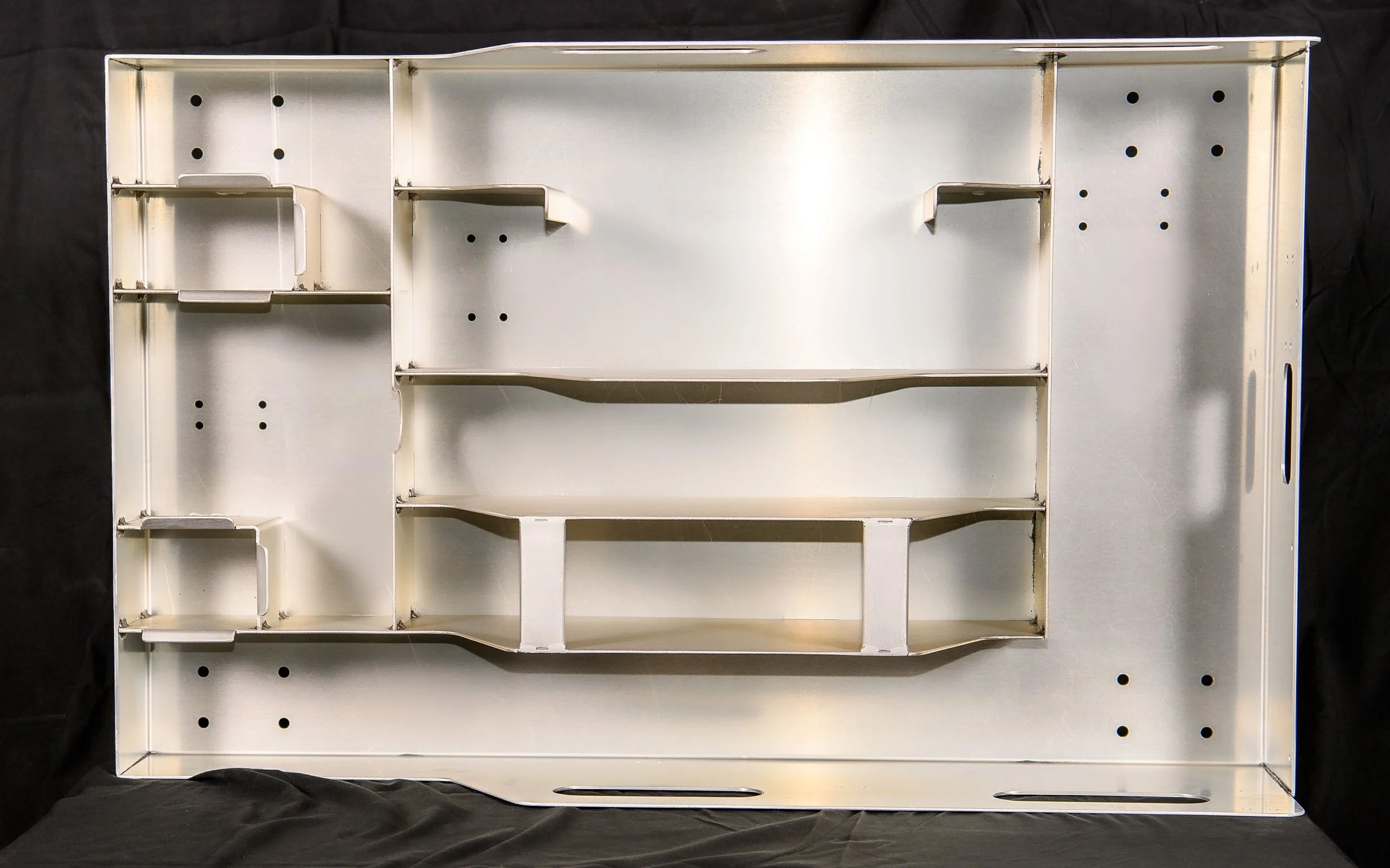

Once those edges are smooth, we move the project to press brake forming. We turn our 2 dimensional flat sheet of metal into three dimensional products.

After those pieces are formed, the project moves to Spot Welding, PEM assembly or Welding.

For example: electronics housings will need PEM assembly for stand off points to insert a printed circuit board.

A housing for a water purification system will move to our MIG and TIG welder who can create sturdy frames which can tolerate the weight the assembly will need to bear.

When products have been painted, we can do light assembly and kitting putting products together.

Then, we box them up, put them on a pallet and ship the product to you with our own dock truck or your preferred method of transportation.